Model:

FC-ZMG 3-24

Brand:

FC(fuchang)

Capacity:

2,800-3,000 pcs/hour

| Product Name | Rotary Type | |||

| Model: | FC-ZMG3-24 | FC-ZMG4-32 | FC-ZMG5-40 | FC-ZMG6-48 |

| Capacity: | 2800-3200Pcs/hr | 3800-4200pcs/hr | 4800-5200pcs/hr | 5800-6200pcs/hr |

| Forming Mold: | 24pcs | 32pcs | 40ps | 48pcs |

| Transfer Mold: | 3pcs | 4pcs | 5pcs | 6pcs |

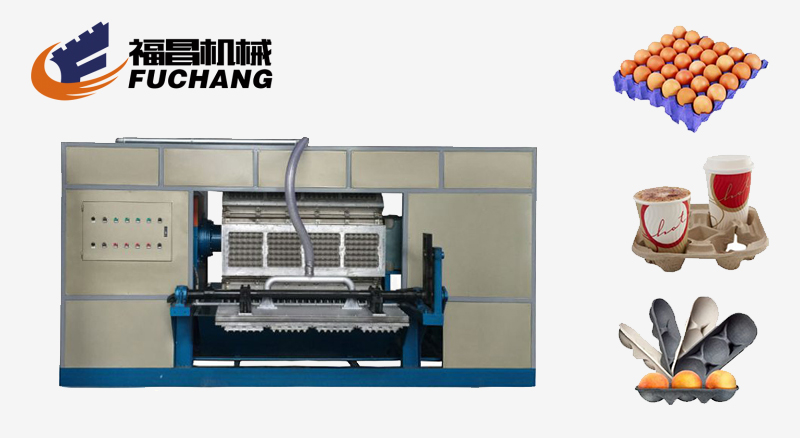

Pulp Moulding Machine is a kind of waste paper recycling machine,It can use almost all kind of waste paper as material to produce different Pulp Packing Product,Such as:Egg Tray,Egg Boxes,Apple Tray,Shoe Insert Tray,Wine packs,Industrial Packing Tray,Berry Punnets,Kidney Tray,Drink cup carrier,Peat Pot,etc.

Rotary type are the most popular model for big capacity request.And Rotary type forming machine had three type:4Ribs,8Ribs,12Ribs.

We have 4 model for 8Ribs Rotary type forming machine:FC-ZMG3-24,FC-ZMG4-32,FC-ZMG5-40,FC-ZMG6-48

Capacity is 3,000Pics/hr.4,000Pics/hr,5,000Pics/hr,6000Pics/hr for 30cavity Paper Egg Tray Producing.

Place of origin: Shandong, China

Brand: FUCHANG

High Capacity Egg Tray Machine FC-ZMG3-24 bring in advanced technology to develop and exploit our own FC brand products. It gets good comments from customer and gain social acceptance in society as a result of its excellent performance characteristic. The main part of High Capacity Egg Tray Machine FC-ZMG3-24 use stainless steel material ,other auxiliary parts of Egg Tray Machine adopt domestic famous brand. We already develop automatic counting stacking and packing system etc.FC series Drum Type Egg Tray machine features of high efficiency, low maintenance and energy saving .The pulp molding system can use all kinds of waste paper to produce high quality molded fiber products .With different moulds it can produce egg trays, vegetable trays, fruit trays, can trays, seedling tray, etc.

Our pulp moulding machine is an kind of waste paper recycling machine.

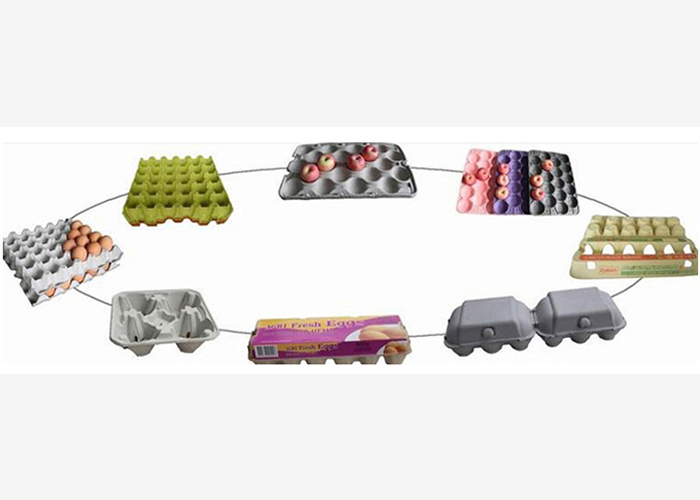

With a different mold,Our machine can produce different pulp moulding product

Egg trays/ 6 cells egg box / 10 cells egg box / 12 cells egg box;

Fruit trays / cup trays / seeding cups / agricultral cups / shoe tree;

Innner industrial packages, like for TV, fan, battery, air conditioner and other electrical items

Disposable Medical Care Products, like Bedpan, sick pad, urinal pan

We can design and produce mold by custom’s request and sample.

We supply 6061Aluminum Alloy Pulp Mould with high quality to make sure the quality of fiunal pulp moulding product

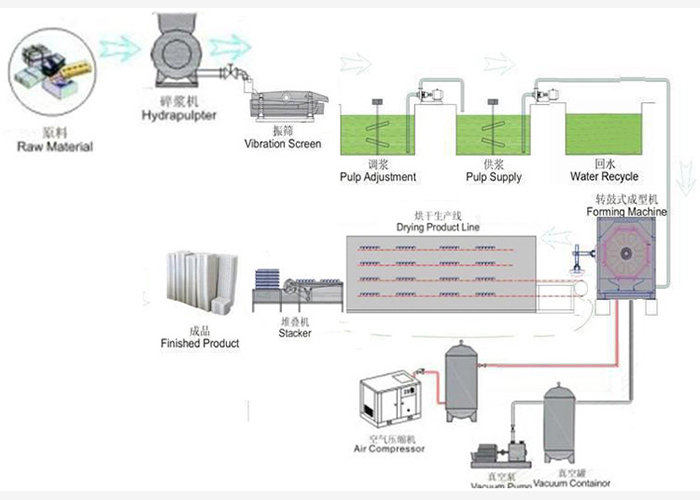

After take sanitary measures of the waste paper, put the waste paper into hydrapulper with water. After progress of batting pulp , grind pulp, size mixing, then send the pulp into molding machine by pump. The foaming mould continuously uniform rotation, the mould absorb the pulp by vacuum, the pulp which adsorb to the mould uniformly dehydrate by Filter and Dehydration hole, Guarantee product and the mould compatibility. when the foaming moulds matched with transfer moulds ,the automatic control system send compression air to control the forming molds, at the same time, transfer mold form a vacuum, the product is send to the transfer mould , then the transfer mold put the product on to the conveyer belt of drying line. The Egg Tray Machine line also equipped with automatic packing ,automatic stacking and counting system so the products can packing well.

The whole |Rotary Type Egg Tray Machine include Pulp Making System + Forming system +Drying system +packing system

(1):Pulping system Egg Tray Machine:

Paper pulp making is the first step of the pulp mold products .

The major equipment Inculding:Hydraulic pulper ,pulp pump ,water pup ,stirrer ,screen machine(vibration sieve) ,refiner machine and control cabinet.

(2): Forming system of Egg Tray Machine:

This part mainly is the egg tray forming machine. We could produce the forming mould and transfering mould based on our customers request. The material of the mould could be Alumminum, Resin, Plastic.

(3): Drying system:

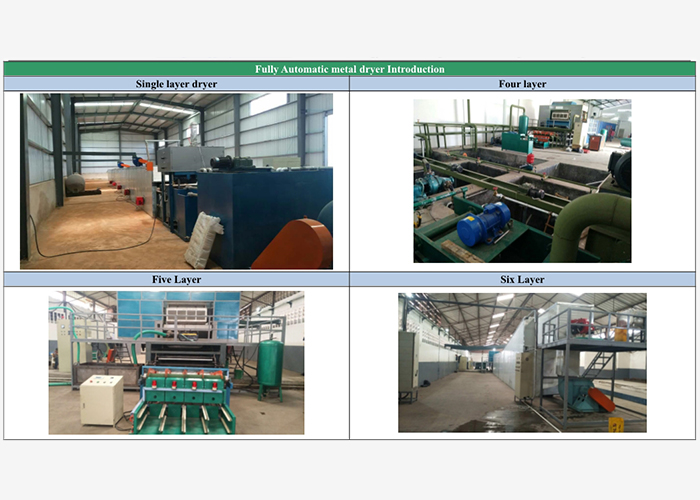

We supply fully automatic metal dryer to our client.

It have two model: Single layer and Multi layer dryer

Single layer dryer run smoothly,multi-layer dryer can save space

(4): Packing system:

The major equipment Inculding:

Converyor+Auto counting machine+Auto press machine.

We supply fully automatic metal dryer with our forming machine.

We can supply single layer and multi layer dryer.

The main energy used to dryer the pulp moled products such as egg tray,egg box/egg carton,fuit tray,industrial tray can be cosen from 0#diesel oil,natrual gas,LPG,Heavy oil,coal,electricityetc,depending on local cost.

the energy consumption of our company drying line is 20%-30%less than the same domestic industry because the good design of dryer.

Multi layer dryer including:3Layer,4Layer,5Layer,6Layer.

Single layer run smoothly,Multi-layer dryer can save space.

Mold is the most imporatant part for Pulp Moulding machine,It will decide the quality of final product of prodcution line

We can offer the mould draft design for customers. Apart from designing and producing moulds for customers, we also provide the professional training and technical supporting in mould design and production.

We can also customize customers’ design, pattern and dimension, then the required molds will be made to fit for products to be packed.

Fuchang Was set up in 1995, over 23 years experience in this field, Chinese reliable supplier, supported by the government and university.

Making the good quality paper tray products lies in the moulds.We’ve acquired many experiences in moulds-making and owned a professional technician team to make mould according to customers’ requirement.

We have our own CNC and mold processing centres, to make sure a good polishing surface and high accuracy.

Mould quality guaranteed;

CAD-CAM design program with high accuracy;

Polishing and processing with CNC machine with compact surface;

Mould maintenance and repaire training;

With hundreds of mould designs, like egg tray mould, egg carton mould, tableware mould, fruit tray mould, medical care products mould, and etc.

1. CAD software design according to customers’ design, pattern and dimension or sample.

2. Put aluminum block into CNC machine for processing and polishing.

3. Drill holes on mould dies reasonably for pulp and water flowing away.

4. Cover the stainless steel wiremesh on the forming mould for pulp suction.

5. Assembly moulds and polish again.

Mould quality guaranteed;

CAD-CAM design program with high accuracy;

Polishing and processing with CNC machine with compact surface;

Mould maintenance and repaire training;

With hundreds of mould designs, like egg tray mould, egg carton mould, tableware mould, fruit tray mould, medical care products mould, and etc.

Longkou FuChang Packing Machinery Co.,Ltd has obtained ISO9001 Certificate and CE Marking. Besides, Fuchang is the vice-president enterprise of China Pulp Molding Association. However, we’ve never stopped to go forward. As a leading company for pulp molding equipments in China, we control over the quality of the products strictly.Our products have passed the inspection by China quality and technical supervision bureau. Now we are producing more than 100 kinds of pulp molding machinery exported to over 50 countries.

A professional team with strong cohesion is one main reason why Fuchang achieved success. Employees in this team are senior engineers and technicists who made great contribution to mechanical design and manufacturing, electrification and automation, heat energy, paper making, process engineering, mould design. To solve customer’s potential worries and problem, our engineers are available to customer’s factory for installation, debugging and training. The engineer will provide the operational approach, production process technology, maintenance method.

Our machines have exported to many countries ,such as Egypt ,Ghana, South Africa ,Uzbekistan, Thailand ,Iceland ,India ,Venezuela ,Vietnam and so on .We keep up the management concept of taking customer’s profit into first consideration ,helping customers reduce the production cost ,improving the quality of the products and offering the best after-sale service.

Our Advantage Services:

We have our own developing and manufacturing team, which guarantees that the advanced technology and excellent quality will be offered for our customers.

We support customize service. If any customers have new ideas about the products, we can provide a unique machine to make the products according to your requirements.

For every customer, we will choose the best fit material and components for the equipment.

We have our own mould design and making team. Sophisticated mould designs are available for customer’s selection. We also accept the samples sent by customers and we will design and make out to meet their needs.

Tel: +86-535-8507308

Tel: +86-535-8507308

Add.: Youth-tech Pioneer Park,Langao Town,Longkou,Shandong Province,China

Add.: Youth-tech Pioneer Park,Langao Town,Longkou,Shandong Province,China