Material:

6061Aluminum alloy

Brand:

FC(fuchang)

Process

CNC

| Type | Model | Material | Shipment | Payment |

| Pulp Moulding Mould | Produce by sample | 6061Aluminum alloy | Air cargo/DHL | TT/Western Union |

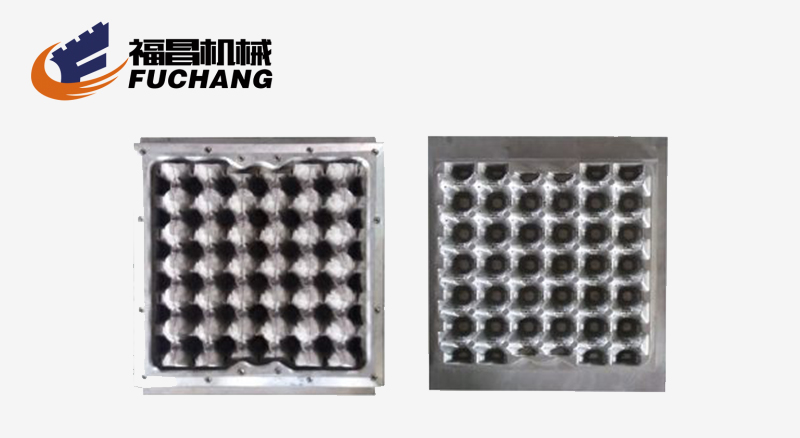

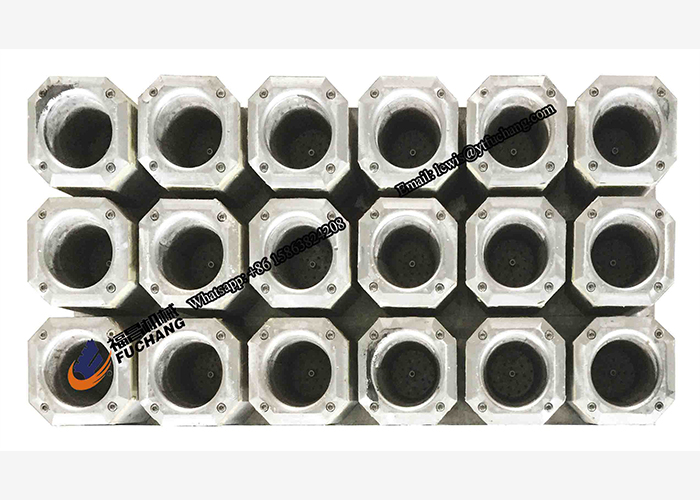

Product Name:Egg Tray Egg Carton Mould Tools.

Specification:30 Holes.

Brand:FUCHANG

Material: Aluminum / Plastic / Copper(Customized)

Design Software: CAD

Shaping Model:Casting or Profile

Application:For Making Paper Egg Tray / Egg Carton

Runner:Hot Cold

Surface Treat: Polishing

Color:Silvery White

Spare Parts:Stainless Steel Wire Mesh

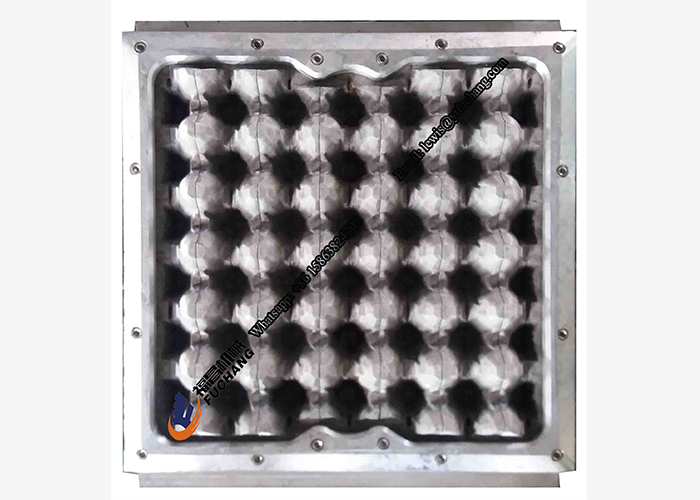

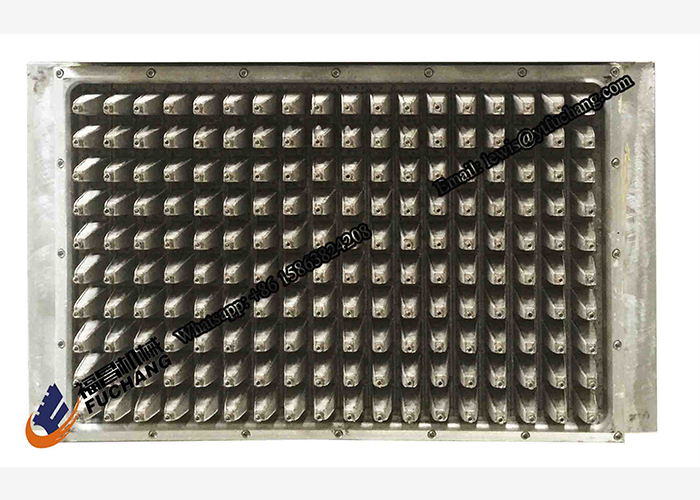

All our molds are designed by computer, and processed by high precision CNC machine, so they are of high precision, high efficiency and excellent quality.

Our purpose is providing first-class quality products, and first-class service. And we strive to build our company into a leading company in pulp molds manufacturing industry, and provide pulp molds with excellent quality and high efficiency to industry colleagues.

Due to our strong technical strength,complete processing and manufacturing equipment,advanced production technology,mature testing methods and standard quality management system,it guarantee that we are able to produce high-quality mold.Our factory has separate departments in packaging design,dies design,manufacturing,testing and selling.the clients will get our professional service in pulp moulding mold.

With the advanced CAD computerized design system and CNC mould processing equipment ,they are of high precision and accuracy, so the customer can get the ideal molded pulp products with thses pulp molds.

Stainless mesh and pre-forming technology will be used in making molds, which makes them look better and increases their efficiency, and thus the products comes out with smoother shape.

We make lineation before drilling holes to ensure all holes distributed evenly. The hole size and spacing of holes of our suction molds are better for high efficiency. We use strainless steel mesh and use pre-forming technology in making it, this make the molds looks better and increase the efficiency, and the products produced are with better looks.

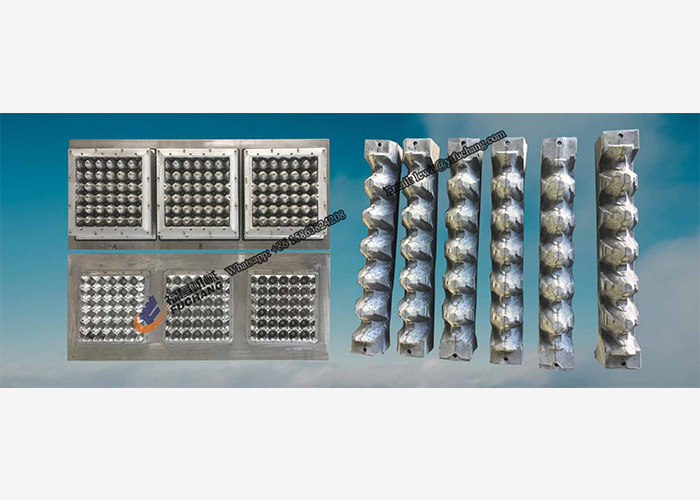

Our pulp molds have been mounted successfully on the international pulp molding machine, such as reciprocating pulp molding machine, rotary pulp molding machine, finery pulp molding machine(products dried directly in the mold). And we made many molds for pulp molding machines made by some famous company in the world.

The molds can be made from aluminum, copper, plastic. According to your requirement. Our mold is durable and easy for maintenance and replacement.

The price of our mold is reasonable comparable to its high quality.

We can customize your existing designs and pattern, and can also design molds as per the products to be packed. All your designs and business information will be kept confidential. If required, we can sign a confidentiality agreement with you.

With the advanced CAD computerized design system and CNC mould processin.

Stainless mesh and pre-forming technology.

Mould Dies Design and Training.

Good material and Advanced Making Method.

High precision and accuracy, get the ideal molded pulp products.

Better appearance, smoother shape, higher efficiency.

Good performance and longer life mould dies.(Over 8 years).

For holding eggs and fruit: Egg Trays, Egg Cartons, Egg Boxes, Apple Tray, Fruit Tray.

Hospital Medical Care Items Toolings: Urinal, Pulp Kidney Dish, Male Urine Bottle.

For holding cups: Cup Carrier, Cup Holder.

For tableware items: Food Holder, Food Tray, Plates, Cup, Lunch Box.

For Molded Fiber Packaging Items: Shoe Insert, Shoe Tray, Seeding Cups, Industrial Inner Packages.

We can offer the mould draft design for customers. Apart from designing and producing moulds for customers, we also provide the professional training and technical supporting in mould design and production.

We can also customize customers’ design, pattern and dimension, then the required molds will be made to fit for products to be packed.

Fuchang Was set up in 1995, over 20 years experience in this field, Chinese reliable supplier, supported by the government and university.

Making the good quality paper tray products lies in the moulds.We’ve acquired many experiences in moulds-making and owned a professional technician team to make mould according to customers’ requirement.

We have our own CNC and mold processing centres, to make sure a good polishing surface and high accuracy.

Mould quality guaranteed.

CAD-CAM design program with high accuracy.

Polishing and processing with CNC machine with compact surface.

Mould maintenance and repaire training.

With hundreds of mould designs, like egg tray mould, egg carton mould, tableware mould, fruit tray mould, medical care products mould, and etc.

1.CAD software design according to customers’ design, pattern and dimension or sample.

2.Put aluminum block into CNC machine for processing and polishing.

3.Drill holes on mould dies reasonably for pulp and water flowing away.

4.Cover the stainless steel wiremesh on the forming mould for pulp suction.

5.Assembly moulds and polish again.

Mould quality guaranteed;

CAD-CAM design program with high accuracy;

Polishing and processing with CNC machine with compact surface;

Mould maintenance and repaire training;

With hundreds of mould designs, like egg tray mould, egg carton mould, tableware mould, fruit tray mould, medical care products mould, and etc.

Longkou FuChang Packing Machinery Co.,Ltd has obtained ISO9001 Certificate and CE Marking. Besides, Fuchang is the vice-president enterprise of China Pulp Molding Association. However, we’ve never stopped to go forward. As a leading company for pulp molding equipments in China, we control over the quality of the products strictly.Our products have passed the inspection by China quality and technical supervision bureau. Now we are producing more than 100 kinds of pulp molding machinery exported to over 50 countries.

A professional team with strong cohesion is one main reason why Fuchang achieved success. Employees in this team are senior engineers and technicists who made great contribution to mechanical design and manufacturing, electrification and automation, heat energy, paper making, process engineering, mould design. To solve customer’s potential worries and problem, our engineers are available to customer’s factory for installation, debugging and training. The engineer will provide the operational approach, production process technology, maintenance method.

Our machines have exported to many countries ,such as Egypt ,Ghana, South Africa ,Uzbekistan, Thailand ,Iceland ,India ,Venezuela ,Vietnam and so on .We keep up the management concept of taking customer’s profit into first consideration ,helping customers reduce the production cost ,improving the quality of the products and offering the best after-sale service.

Our Advantage Services:

We have our own developing and manufacturing team, which guarantees that the advanced technology and excellent quality will be offered for our customers.

We support customize service. If any customers have new ideas about the products, we can provide a unique machine to make the products according to your requirements.

For every customer, we will choose the best fit material and components for the equipment.

We have our own mould design and making team. Sophisticated mould designs are available for customer’s selection. We also accept the samples sent by customers and we will design and make out to meet their needs.

Tel: +86-535-8507308

Tel: +86-535-8507308

Add.: Youth-tech Pioneer Park,Langao Town,Longkou,Shandong Province,China

Add.: Youth-tech Pioneer Park,Langao Town,Longkou,Shandong Province,China